Self-adhesive plastic, like Con-Tact or other brands, will stick to your original book cover permanently. Nothing against Con-Tact et al, just against adhesive plastic used like this on books.

The risky undertaking of removing self-adhesive plastic from a book (e.g. with heat guns or what not,) almost certainly will cause some damage to the exterior of your original book cover. Not to mention cover coloration changes caused by the glue, even if perfect removal was possible.

If you have ever covered any of your books with self-adhesive plastic, I am here to tell you that you should not do that ever again. Ever.

Instead, use non-adhesive plastic and the zero-damage technique hereby described, which:

- Does not alter the book at all, not allowing any glue or sticky thing to touch any surface of your precious book whatsoever (<= this is single-handedly the most important characteristic.)

- Because of the above, it is easily removable and hence replaceable, without causing any damage to your book.

- Protects the book perfectly.

Needless to say, I love books. Have done and enjoyed some DIY book bindings, book cover reconstructions, and book restorations myself actually. But besides that, I have been protecting most of my books this way since I can remember - for sure since undergrad university times, likely since some time in highschool, possibly even primary school.

First of all, the needed materials. This could not be easier:

- The book you want to protect and cover

- Non-adhesive plastic of your choice, here using a very nice frosted/textured one

- Some Cell-o-tape

- Scissors

- Optional: some tupperware-like container (bare with me.)

And here are the steps:

1) Pre-cut all the pieces of cell-o-tape to be used. We will need exactly 12 pieces, each one about 3-4 fingers long. Have them ready to be pulled and used when appropriate. Normally I stick them all onto the edge of a tupperware before starting:

2) Cut a rectangle of the plastic to use as cover, so that when folding it around your book, you would get at least 3-4 fingers of plastic beyond all the borders of the book. Something like the following:

3) Starting with the back, fold the plastic onto the back cover of the book:

4) Apply pieces of cell-o-tape on both ends of the folded plastic, so that it sticks not to the book, but to the plastic itself. This is the whole essence of what we want to do: never sticking anything to the book directly. As you'll see, absolutely all the cell-o-tape pieces are to land completely on the plastic, never on any part of the book:

5) Do the same folding for the front part, and stick the cell-o-tapes there as well, just as we did for the back:

With that, we are four little cell-o-tape pieces down; eight more to go.

6) Now fold little triangles inwards on each corner of the folds, and then apply tapes on each, again landing the tapes completely on the plastic. You can leave some couple of mm between the triangle and the border of the book, as shown here:

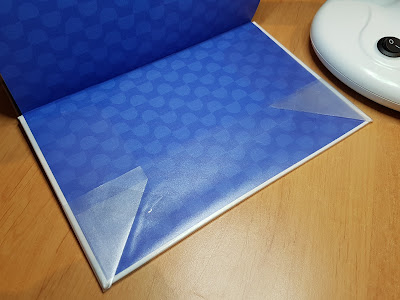

After all four corners are done, we are now eight little tape pieces down; only four more to go. The work so far will look like this:

7) Now near the spine of the book we need to make cuts in the plastic, for the top and bottom folds that will be needed onto the book covers. Two cuts for the front and two for the back, so four cuts in total. This should preferably be done slightly away from the spine edge to make the next step #8 easier:

8) Now starting let's say from the top rear, fold the plastic piece onto the inside of the back cover of the book. A ruler or something similar hard and flat will help a lot in doing this properly. Notice how I sort of pull and pin the plastic down onto the plastic itself which is already folded onto the book cover from the side and from an earlier step:

9) And here comes the magic trick again: apply another little piece of cell-o-tape, this time diagonally, so as to bind that plastic fold coming from the top with the plastic fold coming from the side of the back cover. Yet again: the little sticky tapes are always placed so that they land completely on the plastic, never letting any part of them land on any part of book. They simply hold some of the plastic against some other part of the plastic:

10) Repeat the previous step for the remaining corners, and after that, we are done with the 12 little pieces of cell-o-tape. The work now looks as follows:

11) Now we must finish those little wings of plastic that remain hanging out from the ends of the spine of the book. There are two ways to proceed depending on whether the book is a soft-, or a hard-cover one. Here are both scenarios:

11-A) For soft-cover books: simply trim those little wings of plastic near the spine of the book, and our work is done:

Ta daaaaa!

11-B) For hard-cover books: Some hardcover books have no space between the spine and the spine cover (they might be glued together.) Or even if they are separated, the spine might be too narrow. In those cases, simply proceed as if it was a soft-cover book: just cut the plastic as in step 11-A above.

If there is space between the spine of the book and its cover, and the spine is wide enough, then cut the sides of those little plastic wings, so that you end up with single flaps that can be folded into that space. It is convenient to trim the plastic so that the remaining pieces end up slightly trapezoidal, so wider near the spine's edge, and narrower at the end of the plastic, as shown here for the top flap:

Folding the final little plastic flap into the space between book spine and spine cover:

Push it all the way in, and then, with your fingers, press the plastic softly onto the edge of the spine cover, so that it stays bent and remains put. The same must be done for the bottom flap of course. The end result for a hard-cover book should look like this:

Here a couple of additional photos of this hardcover book showcasing this non-adhesive, zero-damage plastic cover technique:

And here a few more books already covered and protected this way. The yellow one on top does not have the frosted plastic as cover but a completely clear one, so it's hard to see on the photo:

This kind of protective cover is not only super durable, but also perfectly replaceable. If after many years and/or lots of usage that plastic cover looks worn or bad, simply remove it carefully by cutting out the tapes on the corners, unfolding the plastic all the way, removing it, and then going through the process described here once more, covering the book again with a brand new plastic and the same technique: no sticky tiny bit of cell-o-tape ever touching any surface of the book or book cover anywhere. No alteration, no damage whatsoever. Just protection.

Why some libraries keep covering books with self-adhesive plastic really beats me. In any case, I hope this little guide will help you better protect your beloved books.

PS. Step 12) Clean your tupperware! ;)